1060 Series

1060 Series high-speed double-sided tablet presses can complete the pressing process twice in one turret rotation, including filling, dosing,

1. D/B/BB/BBS/HLS14 series punches can be used in this machine without changing

2. Electrical control mechanism adopts B&R PCC (program-controlled computer). Compared with traditional PLC (programmable logic controller), it owns stand-out performance in CPU frequency, data storage, scan cycle,

3. C programming language can realize many functions which can’t be achieved by PLC.

4.

5. Expansion I/O adopts modular design so that non-professionals can also maintain and replace it, and there is no limit of numbers of

6. Our double-sided tablet press is equipped with various interfaces including 232, 485, Ethernet and USB interface.

7. Both program and data are stored in CF card.

8. Double-sided tablet press is equipped with real-time data acquisition and data backup system.

9. Any production records, e-signatures

1. Rigid four-column structure helps to offset forces in operation, ensuring machine can run stably with

2. Traditional hydraulic system

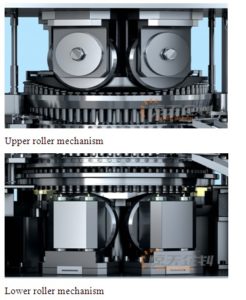

3. Dosing mechanism and lower roller mechanism can be adjusted through worm gear driven by

Dosing and transmission mechanism

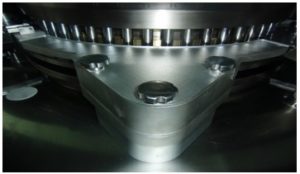

4. Main-press roller structure is the same with pre-compression roller structure (250 mm). Both

5. When pressing oval tablet or concave tablet, large pre-pressure ensure

6. If

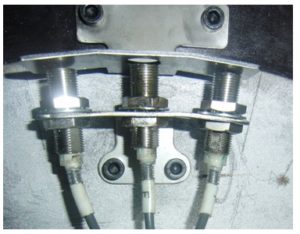

7. Both main pressure and pre-pressure sensors are LCD-22.7Ttt from TEDEA, Germany, which can precisely and directly detect the pressure, thus ensuring the pressure

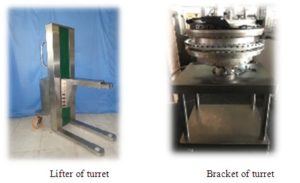

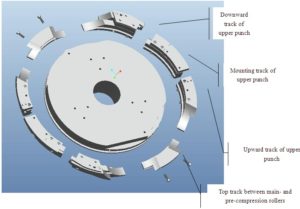

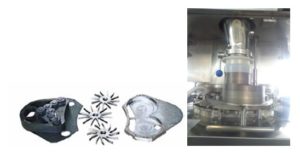

7. Our double-sided tablet press is equipped with modular cam track. Upper cam track is divided into

8. Triple impeller force-feed device controls the flow of powder and ensures the accuracy of feeding.

9. The dust collecting mechanism adopts big wrap angle design, which helps thoroughly clean redundant powder and prevents products from being contaminated.

10. This automatic double rotary tableting machine adopts automatic central lubrication system.

11.

12. Users can set different passwords for safe operation.

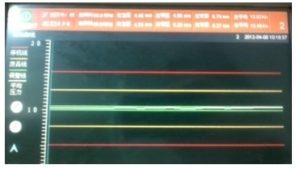

13. Our double-sided tablet press adopts automatic tablet weight control system.

From this picture, we can know the average pressure deviation. When average pressure value (white line) goes beyond preset range (green line),

14. Technological parameters can be saved and invoked, which reduces adjustment time.

15. Our equipment can be used for

| 1060 Series | ||||

| Model | GZPT-122 | GZPT-113 | GZPS-95 | GZPS-76 |

| No. of Stations | 122 | 113 | 95 | 76 |

| Tooling type | BBS | BB | B | D |

| R.P.M | 6.8˜68 rpm | 5.1˜51 rpm | ||

| Max output (tablets/h) | 1500000 | 1037000 | 872000 | 697000 |

| Main motor power | 18.5kW | |||

| Main pressure | 100KN | |||

| Pre-pressure | 100KN | |||

| Max tablet diameter | 11mm | 13mm | 16mm | 25mm |

| Max length of irregular tablet | 13mm | 16mm | 19mm | 25mm |

| Max filling depth | 20mm | 20mm | 20mm | 20mm |

| Max tablet thickness | 8mm | 8mm | 10mm | 10mm |

| Pitch circle diameter | 1060mm | |||

| Diameter of punch | 19mm | 19mm | 19mm | 25.35mm |

| Dimension | 1720 x 1720 x 2182mm | |||

| Weight | 8000kg | |||

Contact Us

Dr. Pharm USA, Inc.

215 Jason Ct.

Corona, CA 92879

USA

Tel: (951) 520-0022

Fax: (951) 520-0033

Contact Us

Dr. Pharm USA, Inc.

215 Jason Ct.

Corona, CA 92879

USA

Tel: (951) 520-0022

Fax: (951) 520-0033